Past Projects (Fast Radius)

This is a collection of some of my faborite past projects from my time as a Design and Development Engineer and Research and Development Engineer at Fast Radius/Sybridge. All renders are my own (Rhino with Octane or Blender, in case Jerry is reading).

3D Printed Lattice Shoe

- 100% 3D Printed with HP MJF (TPA)

- Personalized, lattice midsole with field-driven stiffness

- Integrated, woven lattice upper

- Fu nctional prototypes printed This was a functional prototype I developed with my colleague and mentor Jerry O’Leary. After we came up with the base sneaker design, I designed several zones of elastomeric lattice structure combined with the solid components to form a cohesive, single-piece design (apart from laces).

The upper is a woven lattice structure using a custom latticing method I developed. The midsole is a tuned lattice structure with zonal stiffnesses designed using Grasshopper, nTopology, and some custom tools. The lattices are parametric and can be easily updated for different shoe sizes or mechanical performance. These prototypes were made using MJF technology and TPA material. Several of these prototypes have been printed and worn around in various sizes.

Injection Molded Handles

- Injection molded clamshell assembly

- Glass filled nylon substrate, TPU overmolding

- Functional prototypes (T1 samples) in field testing

This was a design for injection molding project. We took the initial concept design, a tool handle needing to withstand specific loading and environmental conditions, and performed a redesign for manufacturability. We came up with a design consisting of a clamshell structure (glass filled nylon substrate) for structure and housing internals along with soft, textured, TPU overmolding. We validated the prototype through finite element simulation and additively-manufactured prototypes prior to field testing.

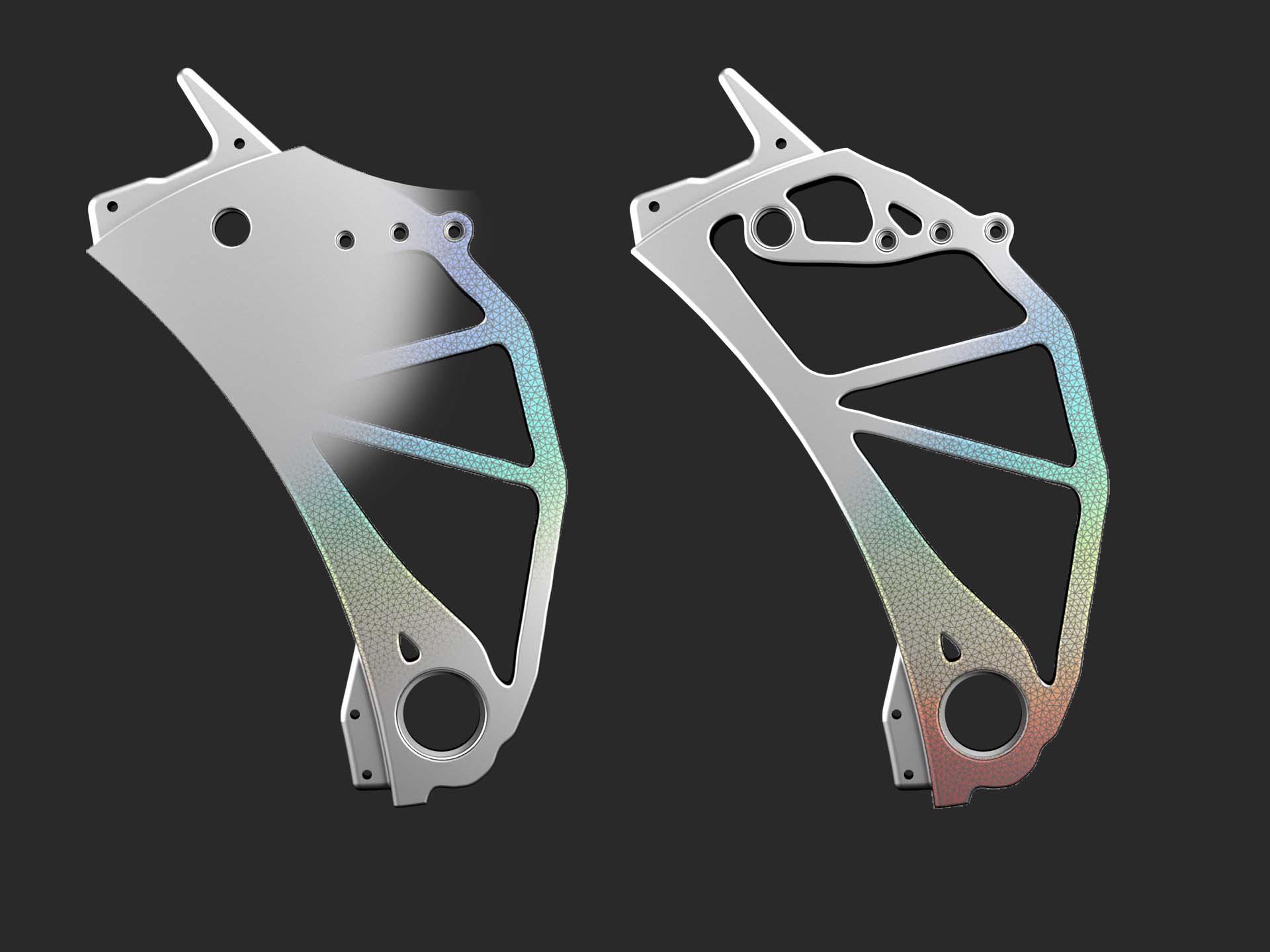

Topology Optimization - Motorcycle frame

- CNC machined aluminum

- Topology optimization of structural compliance

- nTopology (topology optimization), Solidworks (CAD)

This project was for a prototype electric motorcycle. The topology optimization was done for lightweighting and resulted in a 20% weight saving over the original design while still meeting factor of safety requirements.

Lattice Foam Replacement - Ballistics Helmet Liner

- Simulated, tested, tuned for impact performance

- 3D Printed elastomer, MJF

- Grasshopper, nTopology, Abaqus

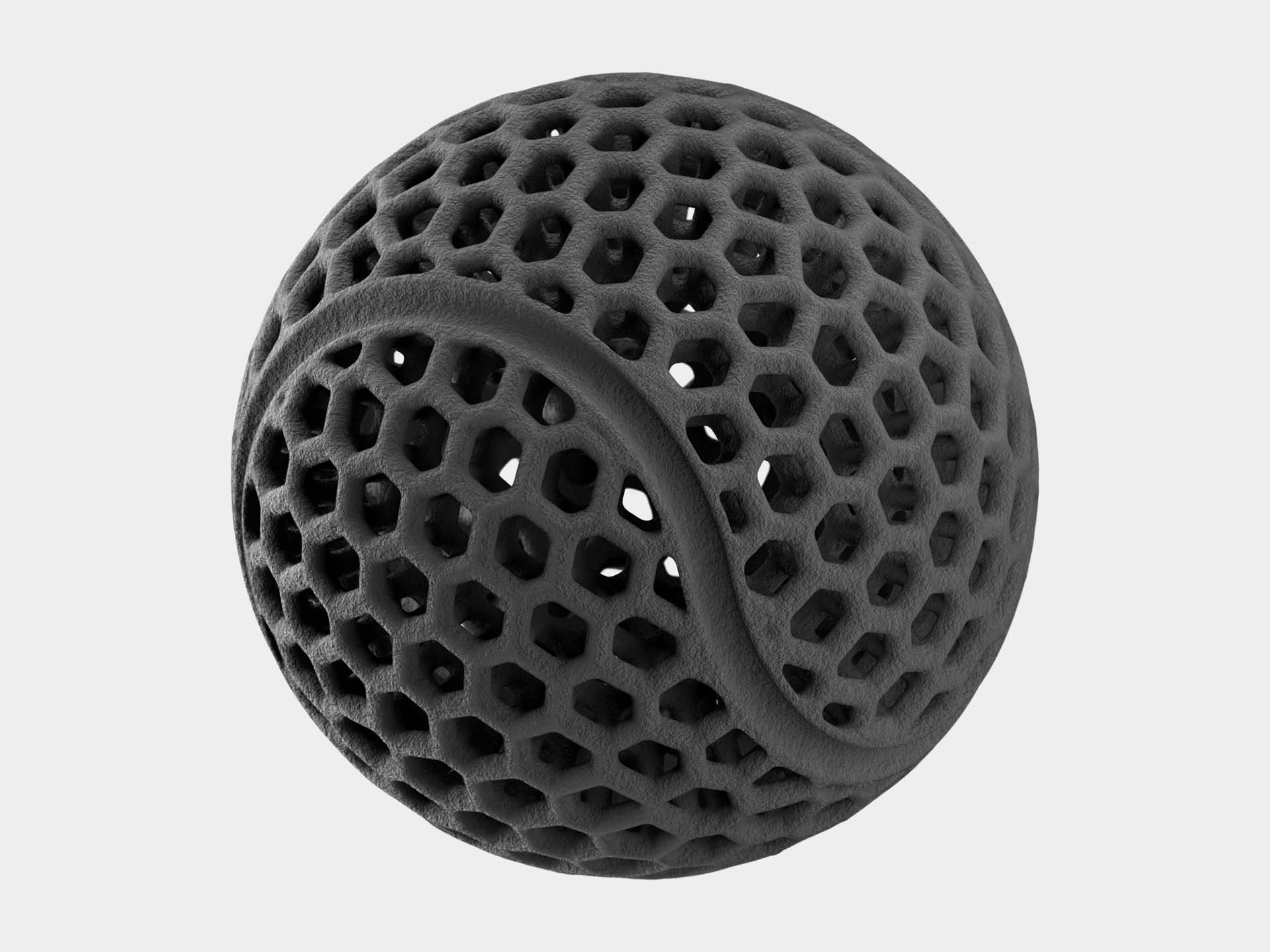

3D Printed Lattice Tennis ball

- 3D Printed with HP MJF (TPA)

- Lattice structure tuned for rebound

- ~150 Functional prototypes printed

This project was a proof of concept prototype for a 3D printed, airless tennis ball. I designed a two-layer custom lattice structure that would withstand the required forces and provide the desired rebound. These were manufactured using HP MJF technology and TPA material. The design involved a combination of Rhino, Grasshopper, and nTopology.